Choosing the right LED bulb supplier can significantly impact the success of your wholesale business. With so many options available, it’s crucial to make an informed decision.

When selecting an LED bulb supplier for your wholesale business, consider factors such as technical support capabilities, competitive pricing without middlemen, quality control, and regional manufacturing strengths. These elements ensure product reliability and cost-effectiveness.

While these initial insights provide a solid foundation, diving deeper into each factor will reveal nuances that could significantly impact your business outcomes. Read on to uncover detailed guidance that can refine your supplier selection process.

Technical support from suppliers ensures product reliability.True

Suppliers offering technical support help maintain consistent product quality.

Regional manufacturing always results in higher costs.False

Regional manufacturing can reduce costs by minimizing shipping and tariffs.

Why Is Technical Support from a Supplier Crucial for Your Business?

In today’s fast-paced business environment, having reliable technical support from your supplier can be the difference between success and failure. Discover why this partnership is vital for your business’s longevity.

Technical support from a supplier ensures rapid issue resolution, minimizes downtime, and enhances operational efficiency. It facilitates custom development, offers expert insights, and maintains product quality. These benefits are essential for sustaining competitive advantage.

Enhancing Operational Efficiency

When technical issues arise, having immediate access to knowledgeable support can significantly reduce downtime1. This means your business operations remain uninterrupted, which is crucial for maintaining productivity levels. Suppliers with robust technical support teams can provide quick fixes and solutions tailored to your specific needs.

Custom Development and Innovation

Suppliers that offer custom development support allow your business to innovate without limitations. Their engineering teams can create bespoke solutions that align perfectly with your company’s goals. This collaboration can lead to groundbreaking products2 that set you apart from competitors.

Ensuring Quality Control

One of the most significant advantages of having supplier technical support is the assurance of quality control. Suppliers can implement stringent checks and balances to ensure the consistent quality of products. With direct quality assurance3 measures in place, your business can promise reliability and excellence to its customers.

Regional Expertise and Focus

Understanding regional differences in manufacturing capabilities can be leveraged to your advantage. For example:

| Region | Focus |

|---|---|

| Guangdong | High-performance, innovative products |

| Zhejiang | Bulk production of popular, ordinary items |

| Jiangsu | Similar focus to Zhejiang |

Working with suppliers who understand these nuances can help your business make informed decisions on where to source products based on your specific requirements.

Rapid Response and Adaptability

Suppliers that prioritize technical support often have quicker response times, ensuring any disruptions are addressed promptly. This rapid response capability is essential in fast-paced markets4, where adaptability and speed are critical to maintaining an edge over competitors.

Technical support reduces business downtime significantly.True

Immediate access to support minimizes operational interruptions.

Suppliers with technical support can't ensure product quality.False

They can implement quality checks to maintain product standards.

How Does Factory Pricing Influence Your Profit Margins?

Understanding the impact of factory pricing on your profit margins is crucial for maximizing profitability. By exploring key factors like cost structures, market positioning, and supply chain efficiencies, businesses can make informed decisions to enhance their financial outcomes.

Factory pricing directly influences profit margins by determining the base cost of products. Lower factory prices can lead to higher profit margins, while higher prices might squeeze profits. Efficient supply chain management and market demand also play significant roles in this dynamic.

The Basics of Factory Pricing

Factory pricing, essentially the cost at which manufacturers sell their products to buyers, forms the foundation of any pricing strategy. It includes production costs5, labor, and materials. Lowering these costs without compromising quality can boost your profit margins significantly.

| Cost Component | Influence on Profit Margins |

|---|---|

| Production Costs | Higher costs reduce margins |

| Labor Costs | Efficient labor increases margins |

| Material Costs | Sustainable sourcing can help |

Role of Supply Chain Efficiency

An efficient supply chain can mitigate high factory pricing by reducing additional expenses6 related to logistics and warehousing. Companies that invest in supply chain technology often see better profit margins due to cost reductions and faster delivery times.

Market Demand and Pricing Strategy

Understanding market demand allows businesses to adjust their pricing strategies effectively. For example, if a product has high demand but factory prices are high, businesses might still achieve favorable margins by leveraging demand-driven pricing models.

Regional Differences in Factory Pricing

Different regions offer varying pricing dynamics based on their industrial strengths. For instance, factories in Guangdong focus on high-performance products, potentially justifying higher prices due to innovation. In contrast, regions like Jiangsu focus on bulk production, offering more competitive pricing.

Exploring regional manufacturing hubs7 can provide insights into optimizing factory pricing strategies that align with business goals. Each region’s focus on either quality or quantity impacts the final profit margins.

Understanding these factors can help businesses craft a strategic approach to factory pricing that aligns with their overall financial objectives and market positioning strategies.

Custom Development and Pricing Flexibility

Some factories offer custom development support, which may come at a premium. However, this can lead to unique offerings that allow for higher pricing strategies. Balancing customization costs8 with potential market demand is key to optimizing profit margins.

By leveraging these insights into factory pricing dynamics, businesses can better navigate the complexities of pricing strategies and enhance their profit margins effectively.

Lower factory prices increase profit margins.True

Lowering production costs boosts margins by reducing base product costs.

Efficient supply chains do not affect profit margins.False

Efficient supply chains reduce logistics costs, improving profit margins.

What Role Does Quality Control Play in Supplier Selection?

In the intricate dance of supplier selection, quality control stands as a crucial partner. Ensuring that suppliers meet high standards is vital for maintaining product consistency and customer satisfaction.

Quality control in supplier selection ensures that the products meet the required standards consistently. It helps in reducing risks, ensuring compliance, and improving overall supply chain efficiency.

Ensuring Consistency and Compliance

Quality control ensures that suppliers maintain consistency in product quality standards9. This consistency is crucial for brand reputation and customer satisfaction. Regular audits and adherence to international standards like ISO help in verifying compliance, which can reduce risks associated with product recalls.

Risk Reduction and Cost Efficiency

By integrating quality control into supplier selection, businesses can significantly reduce risks associated with faulty products. This not only saves costs related to returns and replacements but also protects the company’s reputation. A robust quality control system in place at the supplier’s end ensures early detection of issues.

Enhancing Supplier Performance

Quality control processes enable suppliers to continuously improve their performance. By setting clear quality benchmarks, suppliers are encouraged to innovate and enhance their production processes. This can lead to improved efficiency and better product offerings.

Tools for Effective Quality Control

Implementing a structured quality control system involves using various tools like statistical process control (SPC) and Total Quality Management (TQM) and Design for Six Sigma(DFSS). These tools assist in monitoring production processes and evaluation design if meet SPEC, identifying deviations, and ensuring corrective actions.

| Quality Control Tools | Benefits |

|---|---|

| SPC | Real-time monitoring of production |

| TQM | Continuous improvement of processes |

| DFSS | Design for six segma is a proactive approach to design with quantifiable data and proven design tools that can improve your chances of success. |

Regional Differences in Quality Focus

Suppliers from different regions may have varying focuses on quality. For example, Guangdong factories often emphasize high-performance products, while Zhejiang manufacturers might focus on mass production of everyday goods. Understanding these regional strengths can aid in making informed supplier choices.

By recognizing these regional differences, businesses can select suppliers that align with their quality expectations. This strategic choice enhances competitiveness and product diversity. Understanding the role of quality control in supplier selection is paramount for any business aiming for excellence in its offerings.

Quality control reduces product recall risks.True

Quality control identifies issues early, preventing faulty products reaching consumers.

ISO standards are irrelevant in supplier selection.False

ISO standards ensure suppliers meet international quality benchmarks, crucial for selection.

Why Should You Consider Regional Manufacturing Strengths?

Considering regional manufacturing strengths can offer strategic advantages, from cost efficiency to enhanced quality control. Understanding these strengths can empower businesses to make informed decisions that align with their objectives.

Regional manufacturing strengths provide businesses with cost efficiency, faster response times, and superior quality control. Leveraging these strengths ensures competitive pricing and access to specialized technical support, enhancing overall operational effectiveness.

Cost Efficiency

Choosing regional manufacturing often translates to significant cost savings. Without middlemen, manufacturers can offer the best prices, ensuring you get more value for your investment. For instance, China’s manufacturing12 sector is renowned for its cost-effective production, supported by a robust industrial chain.

Quick Response and Technical Support

Manufacturers located in specific regions can provide faster technical support due to proximity and specialized knowledge. This immediacy means potential issues are resolved quicker, maintaining seamless operations.

Quality Control and Customization

With regional manufacturing, the quality control capability is in your hands. This ensures stable product quality and offers opportunities for custom development13 through dedicated engineering teams.

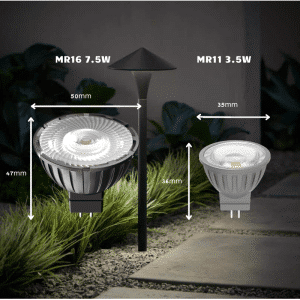

| Region | Focus |

|---|---|

| Guangdong | High-performance, innovative products |

| Zhejiang | Bulk, ordinary categories |

| Jiangsu | Bulk, ordinary categories |

Strategic Location Benefits

Regions like Guangdong focus on high-quality, innovative products, making them ideal for businesses aiming for premium markets. Meanwhile, Zhejiang and Jiangsu specialize in producing popular, bulk items efficiently.

Understanding the focus of each region allows businesses to align their production needs with the region’s strengths, optimizing output and market reach.

Enhanced Competitive Edge

By focusing on a region’s strengths, businesses can enhance their competitive edge. For example, companies leveraging Guangdong’s innovative manufacturing might find a better reception in tech-savvy markets compared to those offering bulk products from Jiangsu.

This strategic approach ensures businesses not only meet but exceed market expectations by aligning products with consumer demands and regional manufacturing capabilities.

Explore how different regions can cater to specific market needs14 and potentially transform business operations through localized advantages.

Regional manufacturing reduces costs significantly.True

Eliminating middlemen in regional manufacturing leads to cost savings.

All regions focus on high-quality, innovative products.False

Only Guangdong focuses on high-performance products; others on bulk items.

Conclusion

Selecting the right LED bulb supplier involves evaluating technical support, pricing, quality control, and regional manufacturing strengths to enhance reliability and operational efficiency for wholesale businesses.

-

Reducing downtime directly impacts productivity, allowing continuous operation and increasing profitability.

-

Custom development allows unique solutions that differentiate your business, enhancing market competitiveness.

-

Quality control ensures product reliability, builds customer trust, and maintains brand reputation.

-

Fast response times prevent prolonged issues, maintain productivity, and enhance customer satisfaction.

-

Gain insights into how production costs impact profit margins and explore strategies to manage these costs effectively.

-

Learn about the role of supply chain efficiency in enhancing profit margins through reduced expenses.

-

Understand how regional manufacturing differences affect pricing strategies and profit margins.

-

Explore how custom development affects pricing flexibility and profit strategies.

-

Explore internationally recognized standards that suppliers must meet to ensure consistent quality across production cycles.

-

Discover why Guangdong factories are noted for their high-performance and innovative products, enhancing supplier selection insights.

-

Learn about the mass production techniques employed by Zhejiang manufacturers to cater to large-scale demands efficiently.

-

Learn about China’s cost-effective manufacturing capabilities and how they benefit global businesses seeking affordable production options.

-

Discover how custom development from engineering teams can tailor solutions to meet specific business needs effectively.

-

Understand how aligning with regional manufacturing strengths can optimize business strategies and meet consumer demands effectively.